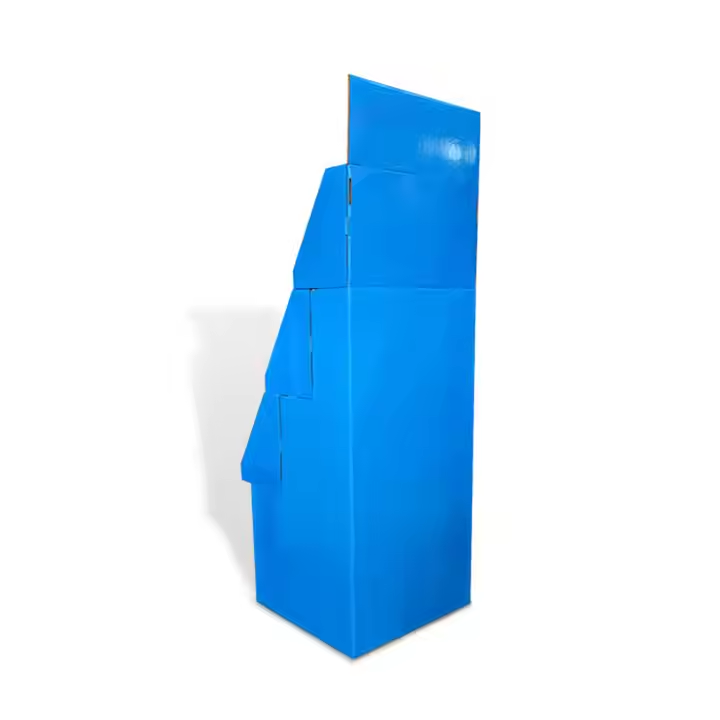

Why does the material of the cardboard display stands in bulk production appear thinner than the samples

By Shenzhen Topwon Group Co.,Ltd

Mar 03, 2024

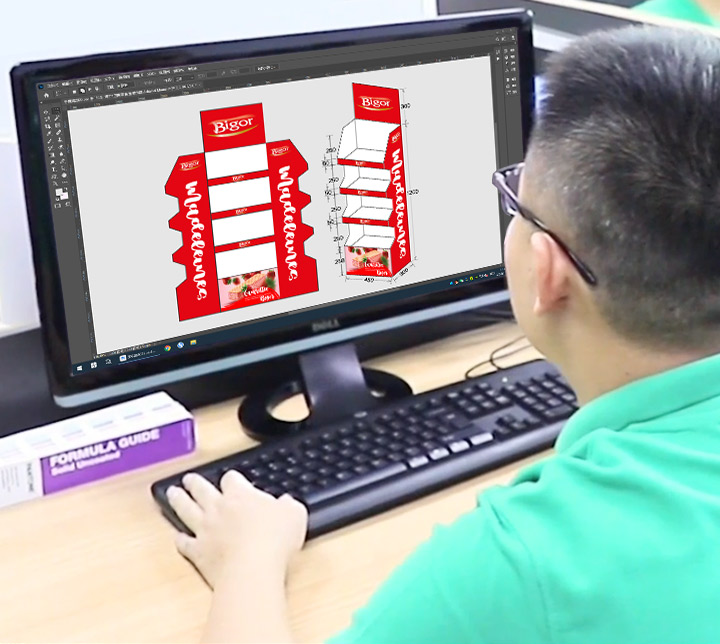

Why does the material of mass production(cardboard diplay) seem inferior to the sample material? It’s noticeably thinner; has the supplier switched materials? Many customers will have such doubts when they receive the bulk goods. Is this really the case? In fact, it isn’t. The materials used for the bulk products of cardboard diplay and the samples of cardboard diplay are the same, but the difference in production processes between the two accounts for the disparity in appearance. Let’s take a detailed look at the difference in processes between them.

Sampling:

The sample cardboard diplay is cut out on a cutting machine using paper specifically for samples. The sample will maintain dimensions and appearance as close to the bulk goods as possible. However, due to the differences in production processes, there are still some discrepancies in the details when compared to the bulk production. The cutting machine is suitable for the production of individual and small quantities of products and is not meant for mass production.

Sample cutting machine. The sample cutting machine cuts paper through the vibration of the motor driving blades.

Sample cutting machine in operation.

The paper cut by the sample cutting machine will maintain the paper’s integrity as much as possible.

Production:

Since the sampling machine is only suitable for creating a small quantity of products, for mass production, a die-cutting machine is used instead. Once the die templates are set up, the die-cutting machine can produce large quantities of formed products in a short time (about thousands of sheets per hour).

When die templates are used, a lot of foam is utilized to prevent the paper from getting caught on the blades, which results in the paper near the blades being compressed. That’s why our die-cut board becomes thinner.

In conclusion:

- We use the same materials for both samples and mass production. The difference in thickness arises from the difference between sampling and production processes, particularly for small parts, which are almost entirely compressed by the foam.

- Sample paper, being stored longer, feels dryer and thus stiffer. The glue used in the current production has not completely dried yet, making it feel slightly softer, but the actual hardness is quite similar.

Trusted by These Featured Clients