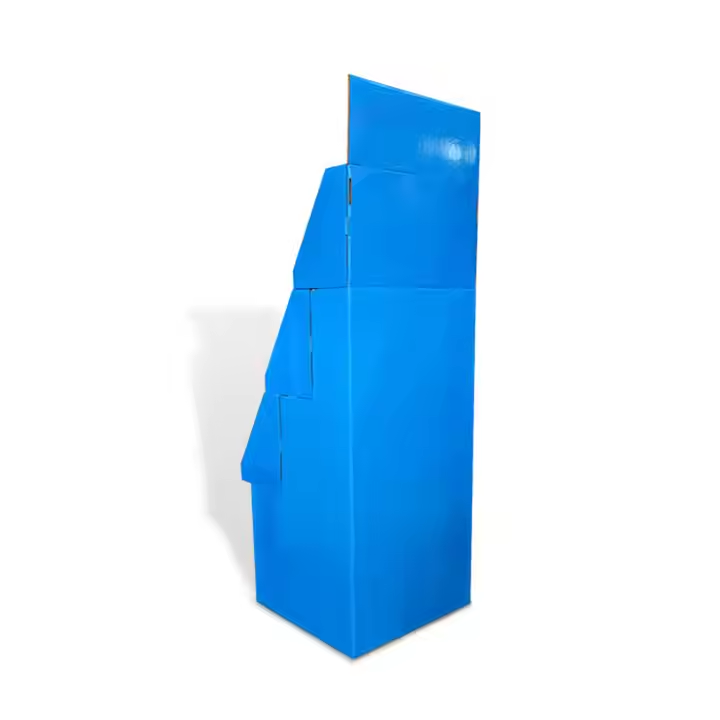

Reasons for charging for custom cardboard display stand samples

By Shenzhen Topwon Group Co.,Ltd

Mar 10, 2024

Prototype creation incurs a charge

In the custom cardboard display stand manufacturing process, factories encounter a critical step: prototyping. This stage not only visibly demonstrates the manufacturer’s professionalism and product intricacies but also directly influences interactions between buyers and sellers. However, customers with experience in ordering cardboard display shelves are aware that prototype creation incurs a charge, often double or multiple times the unit cost of bulk production.

Refunding it upon the client’s subsequent order

While factories initially collect the sample fee with the promise of refunding it upon the client’s subsequent order, several customers still express concern. They query the necessity of charging for a small prototype, considering the factory’s scale, and worry whether the premature fee might affect a successful collaboration, especially before placing any actual orders.

Cost of creating a prototype is

Do you understand how much a worker earns per day nowadays? The process of creating a prototype is typically complex, often requiring at least two days to complete efficiently. It is not a one-person job; at least two individuals are involved. One person assists with the structural analysis and crafting screen cutting lines, while another prepares the print files. Additionally, someone must visit the model room to construct the prototype and another must handle packaging. A single worker may earn 100 per day just for their basic labor in producing samples; hence, two workers can accumulate 400 over the span of two days. The sample itself may not hold significant value, but the materials do, as well as the printing inkjet process and the skilled labor of the craftspeople who create the prototypes. It’s important to recognize not only the tangible costs but also the intangible ones. Materials may be inexpensive, but labor is costly

Standard items may offer free samples

If we produce standard items not requiring customization, we may offer free samples; you would only need to cover the shipping costs. However, if you request a customized design, the prototyping costs at our factory can significantly exceed the per-unit cost of mass production. Take our cardboard display stands, for example: while the unit cost in bulk might be a matter of a few dollars per piece, customizing a single stand could run into hundreds. This is because customization entails creating new die lines per your specifications, confirming and revising the design proofs with you, preparing print files, producing assembly instructions, as well as painting, cutting the prototype, assembling, packaging, and all this process takes about three days or even longer.

Mutual understanding and demonstrating sincerity

In reality, the amount we charge for a sample is not the main issue; what’s crucial is mutual understanding and demonstrating sincerity. If there is an opportunity for placing a large order, we will refund the sample fee. Running a factory is no simple task, and we certainly do not rely on these small sample fees for our livelihood. We collect a minimal amount, mainly to lay the groundwork for cooperation. If clients frequently request samples and then disappear, it can lead to a significant waste of our workers’ efforts, challenging the factory’s operation. Of course, this does not apply to standard products; factories typically have samples readily available for these items, and providing them involves minimal cost and labor.

However, customized products are a different story—they require the meticulous attention of skilled workers in the workshop, and there’s a substantial difference between producing a single item and manufacturing a hundred items.

Trusted by These Featured Clients