The four major processes in the production of display racks

By Shenzhen Topwon Group Co.,Ltd

Nov 04, 2024

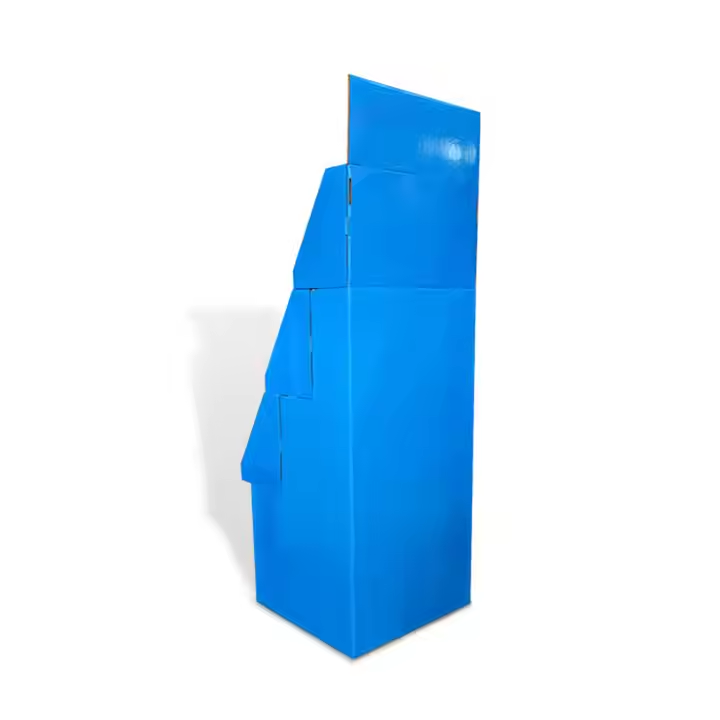

Display racks are now recognized by more and more enterprises, and the market share is steadily increasing. As an emerging product display props, display racks have a beautiful appearance, solid structure, stable performance and other characteristics, has been widely used in cosmetics display, jewelry display, glasses display, cell phone digital products display and other fields. What about the processes in the production of display racks?

Beautifully designed, well-made acrylic display racks can not only better display products, give customers a better shopping experience, but also on the business shopping environment, store perception has a positive role in promoting.

So what process will be used in the processing plant in the display rack? Available 4 points to illustrate the processing method of the display shelf.

Broken grinding method

The acrylic display shelf produced by the broken grinding method is the plate-shaped plexiglass overlapped and pasted together, and then directly grinding section molding. Through the broken grinding method into the acrylic exhibition stand color and lustre, simple and natural.

Hot pressing method

Using hot pressing method of production of acrylic display, first of all, the acrylic sheet heating, and then in the mold hot pressing molding, high production efficiency. This modeling method into the acrylic display with smooth lines, strong sense of three-dimensionality, with the characteristics of relief. Hot pressing mold available wood, oil clay and other shaping, and then cast lead, gypsum materials for yin and yang mold, convenient and quick.

Vertical grinding method

The use of vertical grinding method of production of acrylic exhibition stand and break grinding method has some similarities, also will be acrylic sheet for bonding, directly on the grinding wheel grinding, polishing molding.

Paste method

Adhesive method of production of acrylic display, first of all, the acrylic sheet is cut into a certain shape, and then through the adhesive splicing molding.

The above is just a relatively comprehensive analysis of the production method, in the actual production process, manufacturers are generally based on the structural characteristics of the exhibition stand to be produced, integrated use of various production methods to achieve the best production results.

Trusted by These Featured Clients