Which is better to make acrylic display racks from extruded board or casting board?

By Shenzhen Topwon Group Co.,Ltd

Dec 02, 2024

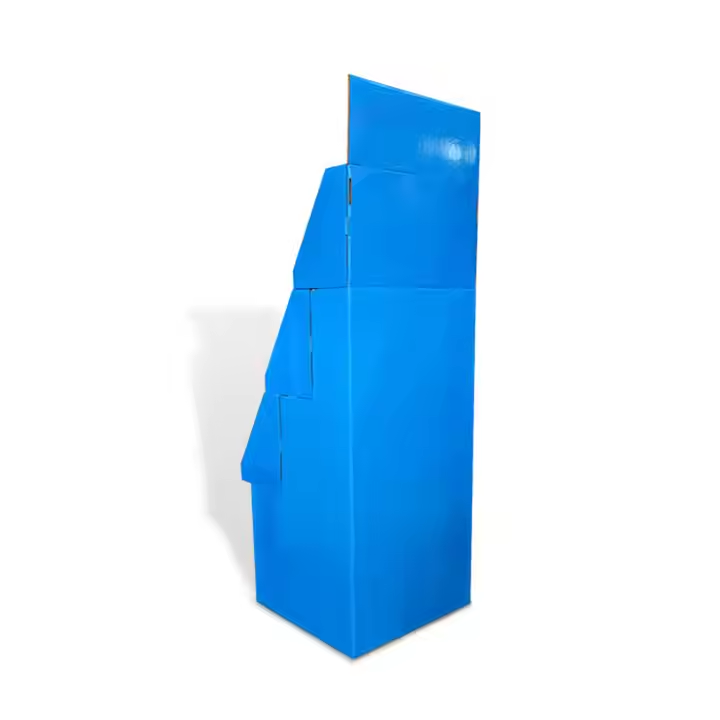

Customers in the purchase of display racks, not necessarily fully aware of the use of display racks material, such as acrylic display racks, commonly used sheet has two types, one is the extrusion plate, the other is the casting plate, which one of the two can be better production of acrylic display racks?

Basic introduction to extruded and cast plates

Extruded plate: acrylic extruded plate is made of hot melt acrylic material extruded by roller;

Casting plate: while the casting plate is made of hot melt acrylic material through the mold molding, cooling and become.

Extrusion plate and casting plate to do the difference between the acrylic display stand

Material purity

Acrylic casting plate material purity is high, for pure organic materials. Extruded plate purity is relatively low, it is difficult to distinguish with the naked eye, but you can check the material description.

Difference in thickness

Due to the limitations of the processing technology, the thickness of the acrylic casting plate can generally do 2 mm -70 mm thick, less than 2 mm casting plate there is no way to process; acrylic extrusion plate thickness can be done to the thinnest 0.5 mm, but the thickest can only be done to 8 millimeters more than 8 millimeters can not be produced. If your acrylic display shelf with more than 8 mm sheet, you can basically judge the use of casting plate.

Thickness error from two rules

From the two thickness error to distinguish, acrylic casting plate thickness error is small, thickness error can be achieved within 0.1 mm; while the thickness of the acrylic extrusion plate error is generally more than 0.2 mm.

Difference in Flexibility

The strength and flexibility of the acrylic casting plate is relatively high, while the acrylic extrusion plate is more brittle, compared to will be more easily broken. This is related to the quality of acrylic and the use of time, you can test the impact resistance of acrylic display racks, for example, drop box test, impact resistance is good casting plate, fragile is extruded plate.

Distinguishing from the process of thermal processing

In the actual thermal processing of the process can also be distinguished, such as in the use of laser cutting, acrylic casting plate through the laser cutting edge is relatively smooth, while the acrylic extrusion plate will appear ripple jagged. This requires timely supervision in the production of display racks, according to the jagged texture to determine the plate

In short, the extrusion plate and casting plate each has its own advantages and disadvantages, when doing acrylic display racks, according to the actual situation to choose.

Trusted by These Featured Clients