Maximizing Impact: Structural Design Strategies for Temporary Corrugated Retail Displays

By Shenzhen Topwon Group Co.,Ltd

Mar 22, 2025

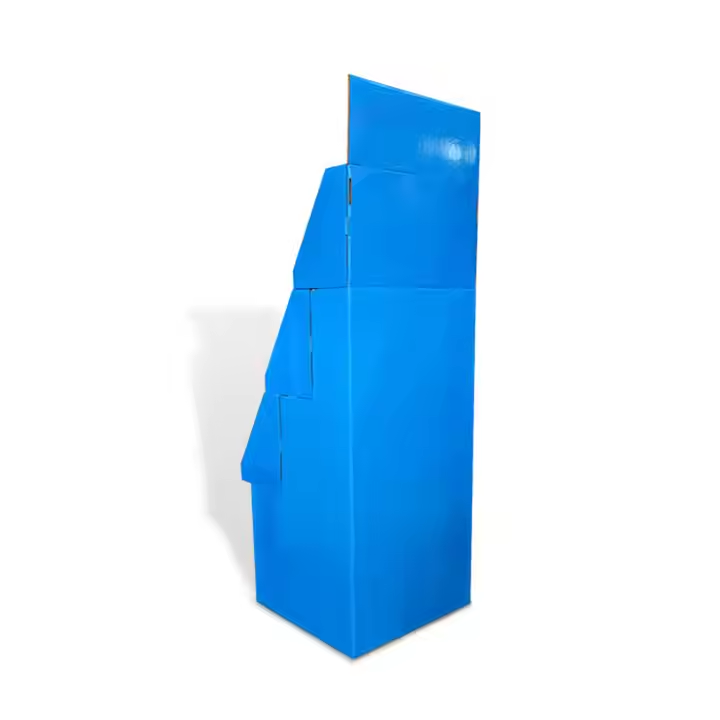

The structure of cardboard display rack is complicated. Structural design is the soul of the cardboard display rack, the shape is ever-changing, to be realized with cardboard is a difficult problem, plus the cardboard to achieve the load-bearing, so the structural requirements are very high. So to make high-quality cardboard display racks must have a good structural designer. Structural design software is also very important, a good software can be half the effort.

Functions and features

Can make the product can get better display. cardboard display stand has economic and practicality, according to customer demand, free design size and printing pattern, pattern color is flexible and beautiful, with high advertising carrying effect. Light weight, small volume, easy to transport after folding and packaging, green materials, can be used many times.

Product performance

All parts are made of high quality gray cardboard + high-strength corrugated pit cardboard, can be folded, can be assembled, assembly without any tools. It can be designed according to customer’s drawing, or according to customer’s requirements and product characteristics.

Commercial use

Advertising promotion, short-term promotion, product display. Suitable for placing in supermarkets, shopping malls, specialty stores, large stores and other places. It is a good advertising tool for terminal stores. Suitable for food, clothing, sporting goods, IT products, daily necessities, automobile products, music, books and other industries.

The good or bad structural design directly affects the quality of the display stand. cardboard display shelf structure design must consider the deformation of the production process, the good and bad materials directly affect the size of the deformation and the load-bearing shelves.

cardboard display shelf production equipment only need to be equipped with a 1800mm and a 1200mm die-cutting machine, a laminating machine and a glue machine, a set of equipment to do the beer plate is good, but now on the market to do the price of the laser knife mold is not high, because the laser knife mold is very high efficiency, generally sent more than 20 square feet to the knife mold factory, only one day can be completed with a human hand at least four to five days. Plus the laser knife mold precision is very high, the product will be made than the proofing machine to do out of the better.

Trusted by These Featured Clients